-40%

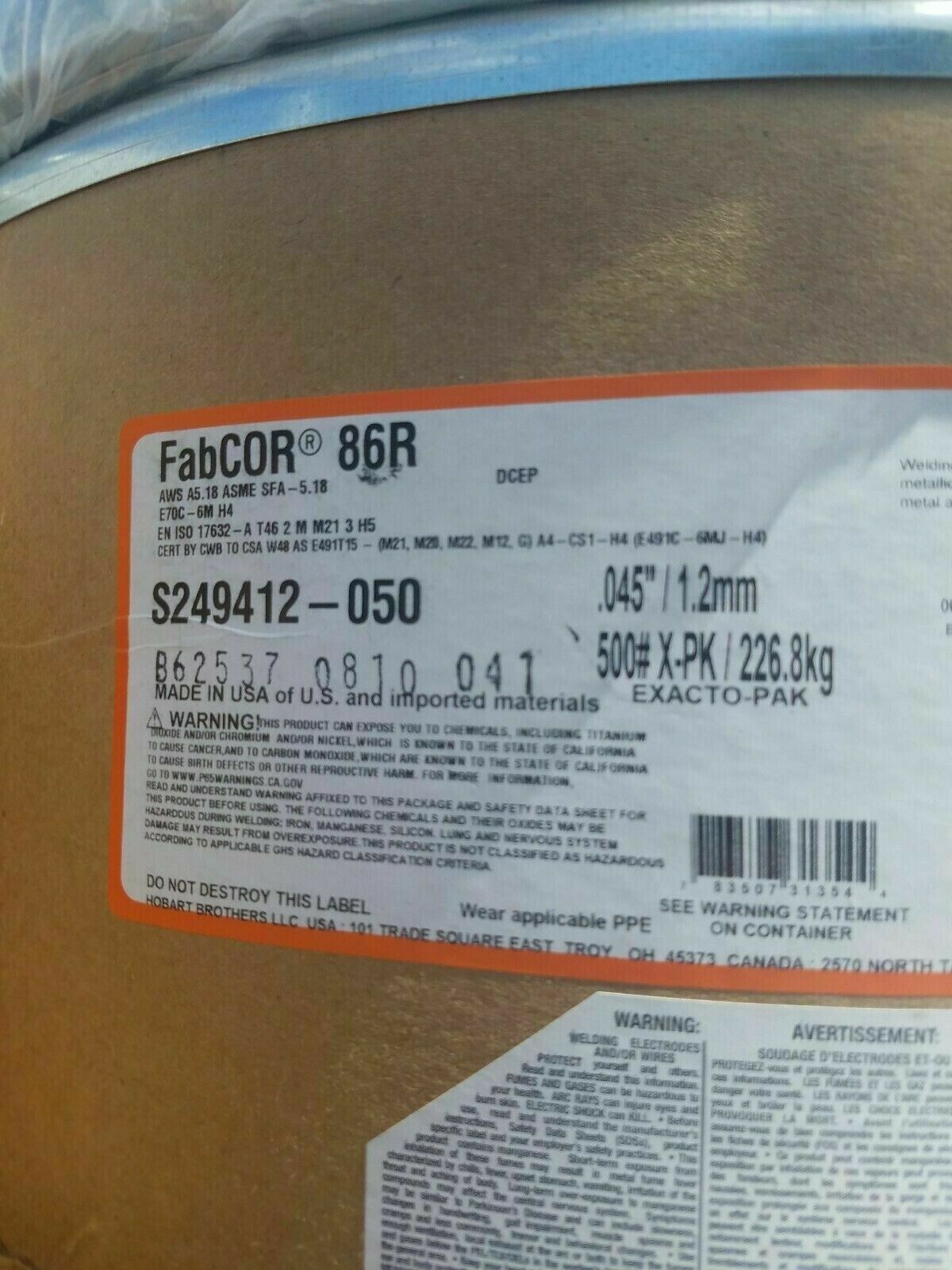

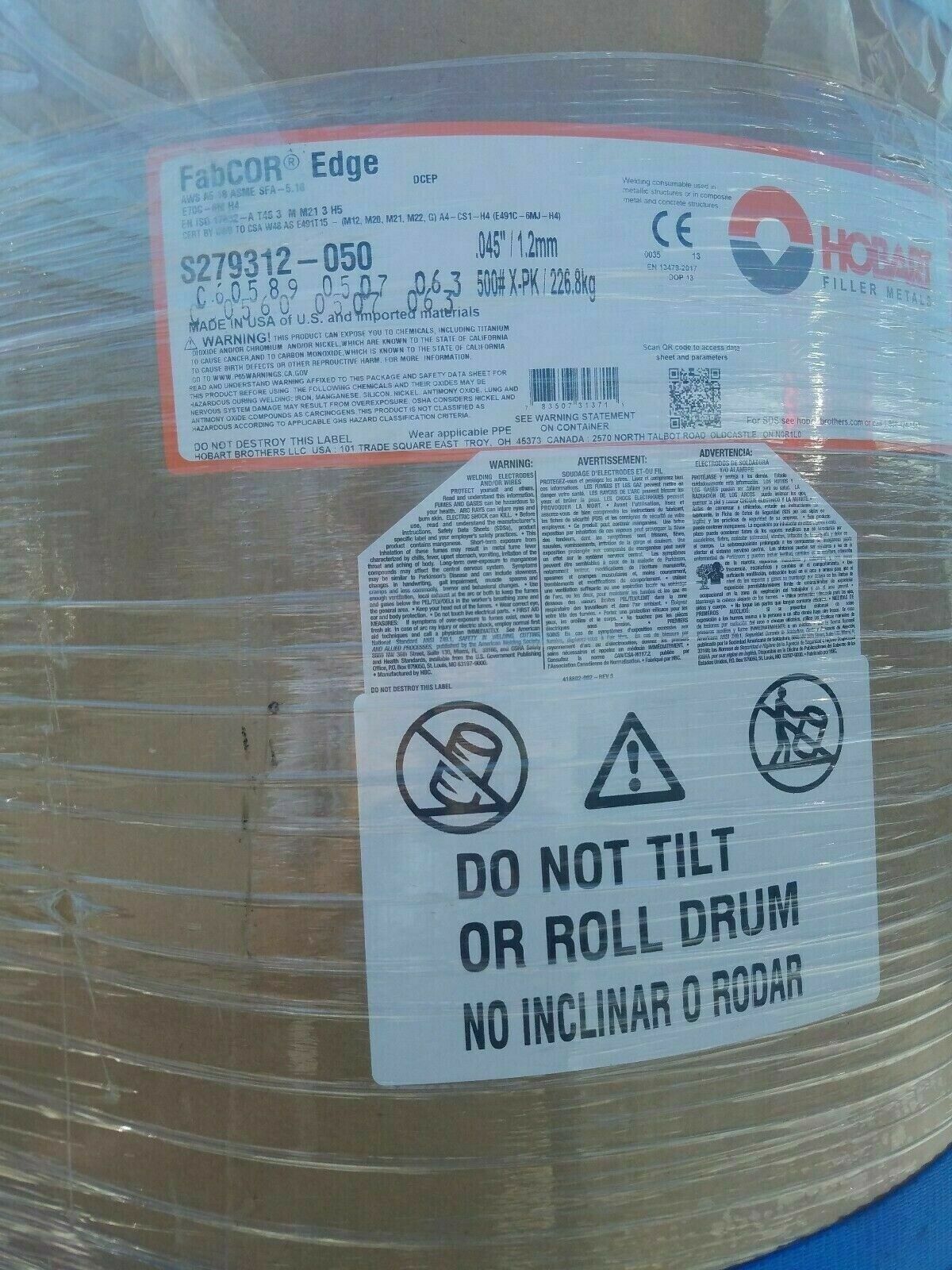

.045" E70C-6M FabCOR 86R Gas Shielded Metal Core Carbon Steel Tubular Welding W

$ 686.39

- Description

- Size Guide

Description

.045" E70C-6M FabCOR 86R Gas Shielded Metal Core Carbon Steel Tubular Welding Wire 4-500 lb DrumsNOTE: THIS LISTING IS FOR 4-500# DRUMS OF WELDING WIRE. THIS LISTING IS LOCAL PICKUP OR LTL FREIGHT SHIPPING PAID BY BUYER. MESSAGE WITH ADDRESS AND WHETHER ADDRESS IS BUSINESS OR RESIDENTIAL AND IF YOU HAVE EQUIPMENT TO UNLOAD.

AT TIME OF LISTING WE HAVE INDIVIDUAL DRUMS AVAILABLE.

HOBART FabCO 86R Gas Shielded Metal Core Carbon Steel Tubular Welding Wire of 0.045" Dia produces welds with consistent weld quality and gives you the high deposition rates of a flux-cored wire along with the high efficiency of a solid wire. Gas shielded, metal powder, metal-cored wire suitable for flat and horizontal welding positions gives low diffusible hydrogen weld deposit and outstanding welding performance. Wire with virtually no slag coverage minimizes the risk of hydrogen-induced cracking. Wire provides high deposition rates as well as efficiencies and has smooth arc characteristics. Wire with low smoke, low spatter and extremely smooth operator appeal promotes versatility and minimizes clean-up time. The enhanced operator appeal, assists in maintaining consistent weld quality. It features a higher level of de-oxidizing elements to handle mill scale welding applications. Wire is great for both CV as well as pulsed welding and can also be used for robotic welding. The deposition rates in excess of 20 lb/hr and deposition efficiencies of 95% and greater can be obtained with the wire's metal powdered core and spray transfer. Wire has a minimum 70000 psi tensile strength, 58000 yield strength and 22% elongation in 2". It promotes versatility in procedure development and provides an outstanding high-production performance. It is associated with E70C-6M H4 class of wires and is used in single or multiple pass applications with argon/CO2 shielding gas. Wire comes in an exacto-pak of 500 lb and is used in shipbuilding, railcar and general fabrication.

Features

Low smoke and spatter levels

Virtually no slag coverage

High deposition rates

Low diffusible hydrogen weld deposit

Smooth arc characteristics

Excellent for both CV and pulsed welding

Outstanding high production performance

Specifications

AWS Class E70C-6M H4

Code and Specification Data: AWS A5.18/A5.18M, ASME SFA 5.18, AWS D1.8/D1.8M

Applications

General Fabrications

Automatic and mechanized welding

Single and multiple pass applications with Argon/CO2 shielding gas

Earthmoving equipment

Steel structures

Storage vessels

Ship building

Non-alloyed and fine grain steels

Rail cars

Caution

Consumers should be thoroughly familiar with the safety precautions on the warning label posted in each shipment and in the American National Standard Z49.1, Safety in Welding and Cutting - published by the American Welding Society

Avoid breathing welding fumes and gases, they may be dangerous to your health

Always use adequate ventilation

Always use appropriate personal protective equipment